The layout of Huaba Intelligent Technology's production workshop is scientific and reasonable, with three core production units: hardware workshop, bending and welding workshop, and installation workshop. These three workshops perform their respective duties and work closely together to form a complete and efficient production chain. As the source of production, the hardware workshop undertakes the important tasks of raw material processing and basic parts manufacturing. Here, various metal materials are carefully selected and preliminarily processed, and then sent to advanced processing equipment for cutting, stamping and other operations according to strict design requirements to provide high-quality parts for subsequent production links.

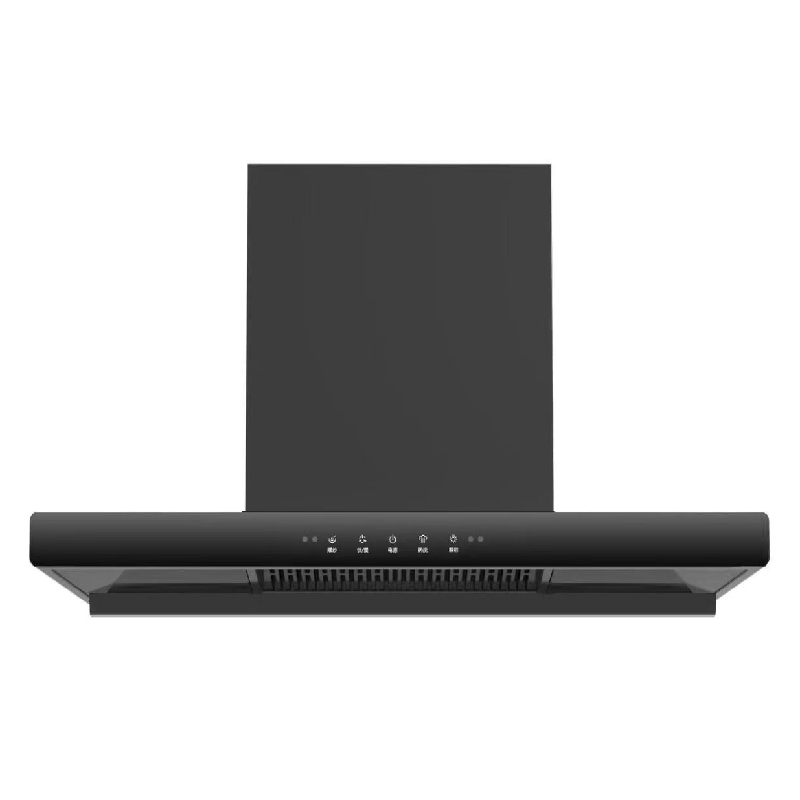

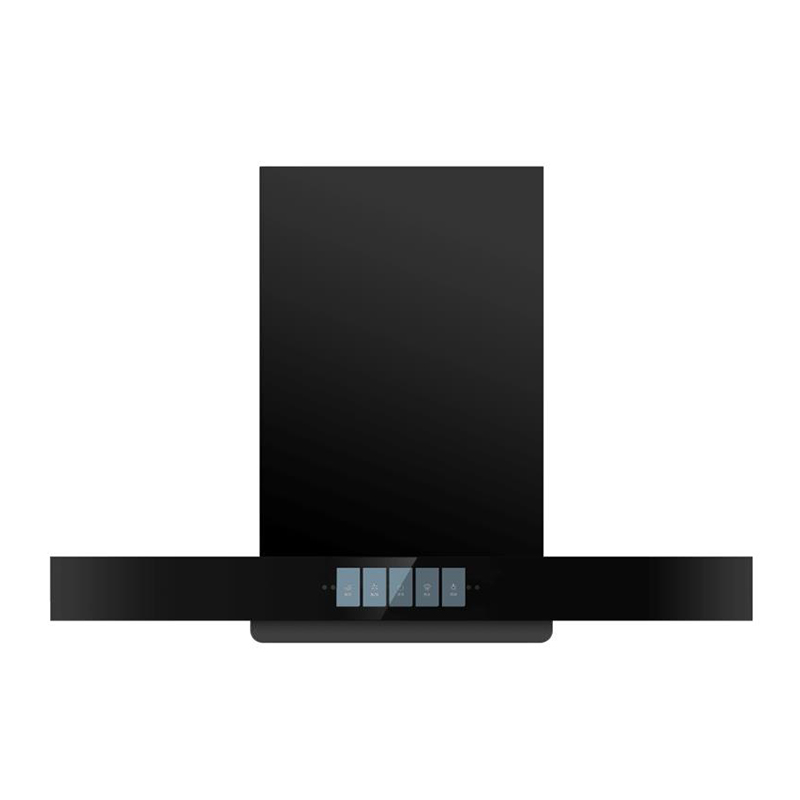

The bending and welding workshop is the key link for the precise assembly and welding of parts produced by the hardware workshop. The workshop is equipped with professional bending and welding equipment. With superb skills, skilled workers cleverly connect the parts together to form the main frame of the range hood. Whether it is a complex bending angle or a fine welding process, it can be perfectly presented here.

The installation workshop is the last checkpoint for product formation. There are 15 installation production lines here with a daily production capacity of 4000-5000 units. On the installation production line, workers strictly follow the standardized operating procedures to accurately assemble each component, and conduct comprehensive debugging and testing to ensure that each range hood can meet high-quality performance standards. The coordinated operation of the three workshops enables Huaba Intelligent Technology to achieve large-scale and efficient production to meet the market's strong demand for high-quality range hoods.